a sudden snap on the production line—another monofilament yarn breaks unexpectedly. Operations halt, defective products pile up, and efficiency plummets due to inconsistent diameter and poor strength. Soon, customer complaints follow—torn fishing nets, failed medical textiles, ruined 3D prints.

At the heart of these issues often lies one overlooked component: the monofilament yarn.

If it’s weak, your product becomes unreliable. If it’s inconsistent, your production turns unpredictable. So, ask yourself:

Is your supply chain your greatest asset—or its weakest link?

If it’s the latter, then it’s time to reacquaint yourself with the unsung hero of modern industry: high-performance monofilament yarn.

Monofilament yarns are made up of single pieces of synthetic polymer fibers that are manufactured little by little. The most used synthetic monofilament yarns are polyester, nylon or polypropylene. In contrast to a multifilament yarn made of more than one strand of filaments, these monofilament yarns are made as whole, unrestricted threads of even construction and no junction. As a result, the monofilaments have characteristic properties that include high strength, long-lasting ability, and wear resistance of silicate material. Such consistency and performance levels have made it easier for the monofilament yarns to find use in places where they are essential because of their rigidity, and this includes industrial textile use of this yarn, cleanliness of space, surgical suture application, etc. They are manufactured with a lot of care to attain the finished quality of the product through fine extrusion in production.

Monofilament yarns are also a type of synthetic structural material, but of the single-strand kind, not made out of multiple twisted fibers. They are typically made of materials such as nylon, polyester, and polypropylene. It serves to enhance the provision of such processing benefits, which are usually induced by other such polymeric systems. Usually, the production of the monofilament yarn is the production of acrylic or polyester yarn, where the fibres are one solid object. This extension of the yarn into such properties as rigidity, elastic recovery, and size, among other factors, can be changed in many cases at the point of manufacture for the anticipated end use of the yarn.

These monofilament yarns have gained much applied knowledge over a wide range of industrial practices owing to their molecular nature. Consequently, moisture, light, UV rays, or harsh chemicals do not alter their performance which makes them useful, in many ways. In such applications, monofilament fibers may be utilized to provide tensile strength (such as the fibers in fishing lines where flexibility but strength is required) or as precision tools (in the case of surgical threads to improve the process and enhance biocompatibility). The qualities of monofilament fibers are such that they aid in high levels of technology and other aspects used in industries.

PET (Polyester) Monofilament yarn:

· Excellent UV resistance

· High strength and dimensional stability

· Good chemical resistance

· Relatively low cost

Nylon Monofilament yarn:

· Higher flexibility and elasticity

· Outstanding abrasion resistance

· Good moisture absorption

· Excellent fatigue resistance

Polypropylene Monofilament yarn:

· Lightest among synthetic fibers

· Floats on water (ideal for fishing nets)

· Exceptional chemical resistance

· Low moisture absorption

Filaments are primarily produced through extrusion, a dominant method in the textile industry. Polymers such as nylon, polypropylene, and polyester are most commonly used due to their widespread availability and suitability. During the process, the polymer is melted inside an extruder barrel and forced through a spinneret containing multiple holes to form continuous filament yarn. These filaments are swiftly spun into yarn and wound onto bobbins as they are extruded. The term "extrusion" refers to the sequence of operations including melting, extruding, cooling, stretching, and ultimately forming the yarn. In some applications, the yarn is further drawn or stretched to enhance its tensile strength and toughness. Finally, the yarn undergoes finishing treatments to achieve the desired shape and properties, ensuring uniformity and enhanced durability for technical end uses. The entire manufacturing process is closely monitored to guarantee that target specifications and performance metrics are met.

① Raw Material Preparation

The process begins with the selection of high-quality raw materials. For polymer-based production, commercially available terephthalic acid is widely used owing to its cost-effectiveness and suitability for obtaining high-purity intermediate compounds. Additional steps, such as incorporating nanoparticles or specific additives into the reaction mixture during polymerization, may be applied to achieve advanced or predefined morphologies under molding conditions.

② Polymer Melt Extrusion

The selected polymer is fed into an extruder, where it is heated and melted. Thermoplastic materials like polyvinyl chloride are favored for their malleability, which imparts softness and a manageable texture to the final product. Heating and subsequent processing stages are carefully controlled to avoid overheating and ensure uniform thermal distribution.

③ Cooling and Solidification

The molten filament is cooled immediately after extrusion, typically using air quenching or water baths. The cooling rate is critically controlled as it influences material properties such as crystallinity or the proportion of amorphous phases.

④ Orientation and Drawing

To produce fibers with enhanced tensile properties, drawing is applied in later stages to induce molecular orientation. Specific patterns and equipment, such as thin liners, are employed to improve the mechanical strength of the yarns—illustrated, for example, in applications requiring high-performance fabrics.

⑤ Heat Setting and Stabilization

The drawn filament is subjected to heat setting under tension at elevated temperatures for a defined duration. This step stabilizes the fiber structure, minimizes future shrinkage, and locks in intended properties such as heat resistance and high strength.

⑥ Quality Inspection and Finishing

After manufacturing, the yarn is inspected for structural consistency and integrity. Tests include break elongation, thermal resistance, and visual examination. The finished product is wound appropriately to facilitate handling, storage, and transportation.

| Parameter | Polyester(PET) | Nylon(PA) | Polypropylene(PP) |

| Diameter range(μm) | 50-2000 | 50-2000 | 100-2000 |

| Fineness range(dtex) | 200-6000 | 200-6000 | 150-5000 |

| Breaking strength(cN/tex) | 40-80 | 40-75 | 30-60 |

| Elongation at break(%) | 15-40 | 20-50 | 20-60 |

| Chemical resistance | excellent | good | excellent |

| UV resistant | excellent | good | medium |

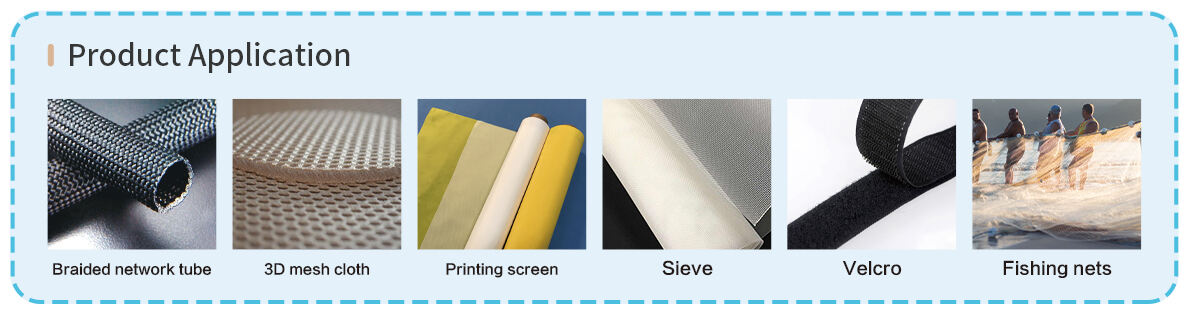

① Medical

The biocompatibility and hypoallergenic properties of monofilament yarn make it an ideal choice for surgical sutures. Its uniform diameter ensures smooth passage through tissue, its high strength ensures secure sutures, and its sterilization resistance allows for repeated sterilization.

②Industrial Screens

The precise diameter control and excellent dimensional stability of monofilament yarn create screens with consistent pore sizes, which are critical for precise separation and filtration applications. Its high abrasion resistance extends screen life, reducing replacement frequency and maintenance costs.

③ Fishing and Aquaculture

Saltwater resistance and high impact strength make monofilament yarn an ideal material for fishing lines and nets. The buoyancy of polypropylene monofilament and the transparency of nylon monofilament provide customized solutions for various fishing applications.

④ 3D Printing and Technical Textiles

The low elongation and high stiffness of monofilament yarn make it an ideal choice for 3D printing reinforcements, providing excellent layer adhesion and dimensional stability. In technical textiles, its consistent performance ensures the reliability and durability of the end product.

With 20 years of experience in monofilament yarn production, we offer:

①Customized formulation design: Polymer formulations tailored to your specific application.

②Specialized performance enhancements: UV resistance, antistatic properties, antimicrobial properties, and more.

③Comprehensive technical support: Full consulting from material selection to application optimization.