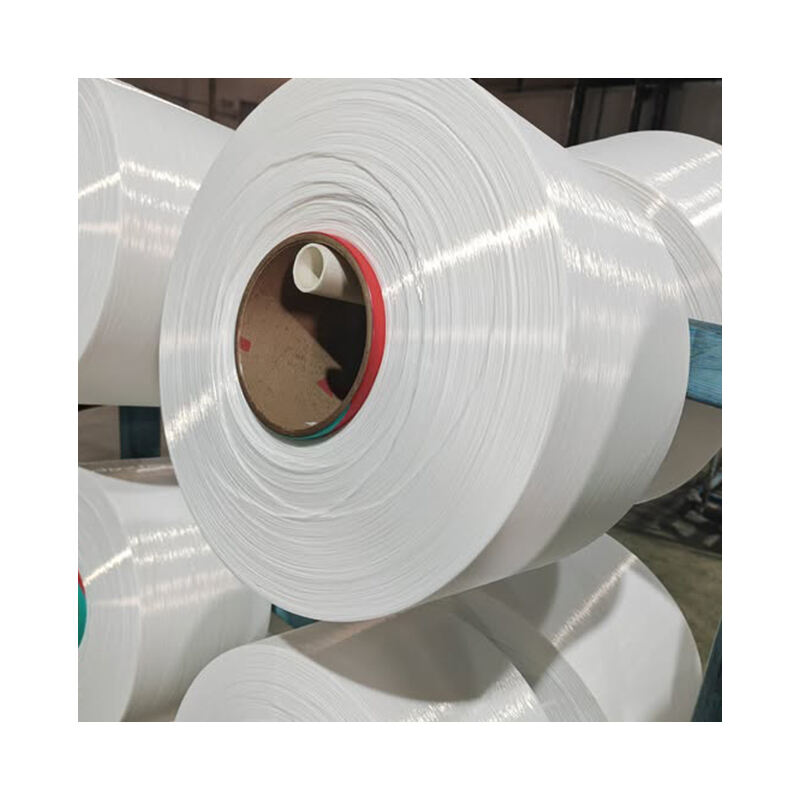

Nylonmødregarn er en specialiseret type nylongarn, der består af flere filamenter snoet sammen, og som er designet til at blive opdelt i individuelle monofilamenter under tekstilbehandling. Denne unikke struktur gør det til et alsidigt materiale til forskellige industrielle og tekstilanvendelser, herunder fladstrikkning, vævning, sari'er, kjoler, myggenet og endda automobiltekstiler.

I denne guide vil vi udforske:

✔ Hvad nylonmødregarn er og hvordan det fremstilles

✔ Nøgleegenskaber, der gør det ideelt til industriel og tekstilbrug

✔ Vigtigste anvendelsesområder på tværs af forskellige industrier

✔ Hvorfor nylon 6-mødregarn er et foretrukket valg til krigelav og strikkede stoffer

Nylonmorderynd er konstrueret med en multifilament-struktur, hvilket betyder, at den består af flere fine nylontråde, der er snoet sammen. I modsætning til standard nylongarn er det specifikt designet til at gennemgå en opdelingsproces, hvor det adskilles i individuelle monofilamenter til videre brug.

✅ Multifilament-struktur – Består af flere nylontråde, der er snoet sammen for styrke og fleksibilitet.

✅ Opdelingsevne – Designet til at blive delt op i finere monofilamenter til specialiserede anvendelser.

✅ Høj trækstyrke – Tilbyder fremragende holdbarhed og modstandsevne over for slid og slitage.

✅ Alsidsighed i forarbejdning – Egnet til flad strikkning, vævning og industrielle tekstilproduktion.

Nylonmorderynd og de deraf afledte monofilamenter er kendt for deres:

1. Styrke og modstandsevne mod slitage

Ideel til anvendelser, der kræver høj holdbarhed, såsom automobiltekstiler og industrielle stoffer. Modstår slid, hvilket gør det egnet til langtidsholdbare produkter som myggenet og tekniske tekstiler.

2. Fleksibilitet og letvægtsegenskaber

De delte monofilamenter beholder nylonets naturlige elasticitet, hvilket gør dem perfekte til strikketekstiler, sari'er og kjoler. Letvægtsmateriale, men alligevel stærkt, hvilket forbedrer komforten i beklædning og hjemmetekstiler.

3. Nylon 6 modertråd: Et foretrukket valg

Nylon 6 anvendes bredt inden for omskråning efter fiberdeling på grund af sin fremragende termiske stabilitet og farveægte egenskaber. Almindeligt brugt i strikketekstiler, og giver en jævn overflade og høj brudstyrke.

Nylon modertråd er et afgørende materiale i flere industrier på grund af sin tilpasningsevne og ydeevne.

1. at Textilindustri

Fladstriknings- og vævningsprocesser – Anvendes ved produktion af fine, lette stoffer til mode og hjemmetekstiler.

Sareer og kjoler – De opdelte monofilamenter skaber bløde, flydende stoffer med en luksus drap.

Myggenet – Sikrer holdbarhed og fin maskekonstruktion til insektbeskyttelse.

2. Automobil- og industrisektoren

Anvendes i sædeovertræk, airbags og forstærkede tekstiler på grund af dets høje styrke.

Anvendt i filtreringsstoffer, transportbånd og industrielle slanger til slidmodstand.

3. Tekniske og funktionelle tekstiler

Medicinske tekstiler – Bruges i kirurgiske net og forstærkningsstoffer.

Sportstøj og aktivtøj – Forbedrer stoffets åndedrætsvenlighed og holdbarhed.

Hvorfor vælge nylon moder garn?

Nylon moder garn adskiller sig som et højtydende tekstilmateriale på grund af dets:

✔ Ekstraordinær styrke og slidmodstand

✔ Alsiddighed i at splittes til fine monofilamenter

✔ Et bredt anvendelsesområde inden for mode, industrielle og tekniske tekstiler

Uanset om du er i beklædningsindustrien, biltekselindustrien eller produktion af industrielle stoffer, tilbyder nylon-modertråd en pålidelig, holdbar og fleksibel løsning.