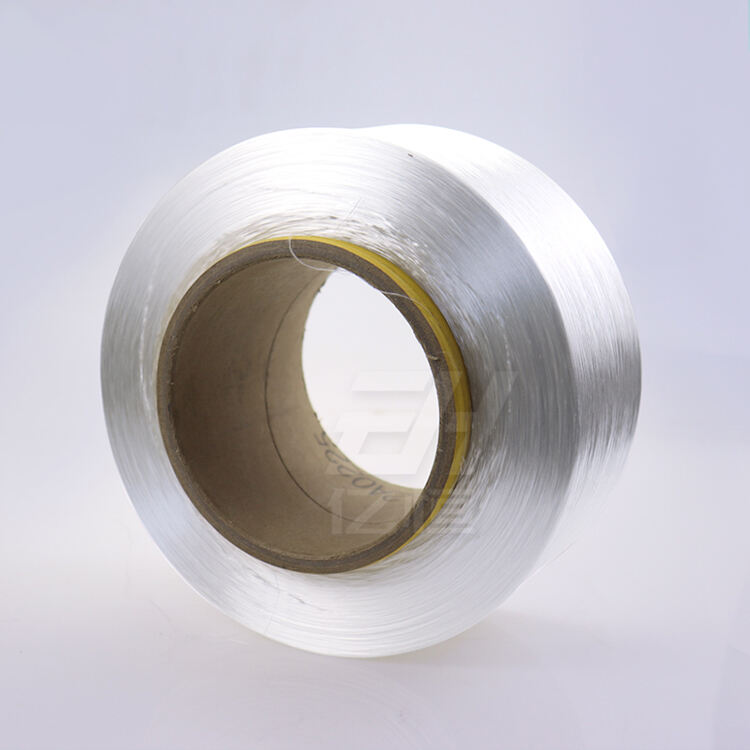

Hot melt yarn, as one kind of versatile material, has been widely used in many fields, especially in textile and nonwoven industry. This special yarn has different advantages in both areas to meet the particular individual demands. In the textile industry, hot melt yarn contributes to higher performance in fabric, and in the nonwoven industry, it also contributes to the nonwoven longer lasting and performing better. Let’s take a closer look at the planet of hot melt yarn and see how it is used in many varied applications and eco-friendly benefits.

Advantages of Using Hot Melt Yarn in Textile Production

Hot melt yarn game-changing Supreme in the textile industry the process of making fabric is breaking new ground. One of the main advantages of using the hot melt yarn in this industry is its strength and durability in the production of stronger, more resilient fabrics. Weft knitted hot melt yarn can add strength and tear resistance to the fabric, using it as a high performance and durable fabric. Furthermore, hot melt yarn adds to the surface appearance of the fabric to yield a smooth, attractive skin. Furthermore, the application of the hot melt yarn in textile weaving loom to replace the conventional sewing provides that traditional sewing is not necessary, thereby greatly shortening the duration and saving money.

Ways in Which Hot Melt Yarn Is Improving Performance in Nonwoven Fabrics

In the nonwoven sector, hot melt yarn is used to enhance the performance of nonwoven fabrics. One of the primary benefits of hot melt yarn in nonwovens is its excellent fiber-to-fiber bonding capability that lets you create a strong and durable fabric even in the face of everyday use. This bonding also has the added benefit of giving the fabric a vertical stiffness to resist stretching and shrinkage over time. Furthermore, hot melt yarn may further improve the softness and flexibility of nonwoven fabric and the comfort of wearing and using of nonwoven fabric in various end uses. In general, the presence of hot melt yarn enhances the value of nonwoven materials by enhancing the quality, functional characteristics, and performance thereof.

Hot Melt Yarn in a Variety of Uses

The application of hot-melt yarn is not limited to the area of textile and nonwoven materials. This new material has wide applications, including the automotive, packaging, medical and geotextile industries. In the automobile field, the hot melt yarn is used to produce interior fabric, seat filling and airbag textiles, bringing comfortability, security and resistant properties. In the packaging area, hot melt yarn is used to form tough and stable padding packaging materials to cushion and protect articles during the course of shipment. Furthermore, in the medical sector, hot melt yarns are applied to wound care, surgical clothing and medical textiles offering hygiene, comfort and protection. With such versatility, it should come as no surprise that hot melt yarn is an invaluable material for a variety of industries, serving so many purposes and working to suit so many needs.

The Various Uses of Hot Melt Yarns at Different Sectors

The uses of the hot melt yarn go beyond the textile and nonwoven fields, into other industries where the special characteristics and advantages are truly appreciated. In the geotextile field, hot melt yarns are employed in the production of geotextile fabrics necessary for soil stabilization, erosion control, and drainage systems. These materials can be used to enhance the structural life of civil construction, providing a robust and sustainable solution. In addition, hot melt yarn is also used in filtration fabric, insulation material and agriculture fabric etc., which demonstrates its wide utilization and versatility in many fields. The wide use of the hot melt yarn indicates that it is a significant material in current manufacturing industry.

Eco-Friendly Benefits of Hot Melt Yarn in the Apparel Industry

In the present time, the environmental factor is important for business all around, also in the textile industry. There are many environmental advantages that hot melt yarn offers, showing us why it is a great product for those businesses looking to minimize their carbon footprint and impact on our world. The use of hot melt yarn in the production of textiles also allows the elimination of solvent based adhesives and chemical binders, among other environmentally damaging waste and emissions. This planet friendly process not only preserves the earth, but also enhances the overall quality and lifespan of the fabric. Moreover, hot melt yarn is recyclable and biodegradable, which benefits a green manufacturing process. Textile applications of hot melt yarn contribute to the increasingly green direction being taken by the industry, and manufacturers seeking to ease their footprint on the environment prefer it.

Hot melt yarn is a flexible, new, and useful product which provides many advantages for textile and nonwoven industry, along with many other fields. Its utilization contributes to an increased performance and quality of textiles, value added non-woven, and the environmental sustainability of manufacturing. The benefits of hot melt yarn Hot melt yarn is beneficial to use among manufacturers who value a combination of factors that will help to enhance their products, save the environment and offer appealing trends to the end-consumer. Use of hot melt yarn Manufacturers use hot melt yarn as a tool to develop this fine art by producing sustainable and durable products that will make them remain in the consciousness of the customers.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

LO

LO

LA

LA

BN

BN

SK

SK

SL

SL